How to Choose a Suitable Sealing Tape

There are many types of tapes, for example, there is a product called sealing tape, many people do not know how to choose a suitable sealing tape,

1. Consider the microporosity of the adhesive object, because the onset of the adhesive effect is that the moisture of the adhesive enters the adhesive quickly and boringly, so that the tape becomes part of the adhesive, so the microporosity of the surface of the adhesive is very important about the choice of tape, if the microporosity is more, the bonding speed of the tape is fast.

2. Pay attention to the adhesive on the surface of the tape, not too wet, otherwise it will be difficult to open when used, and sometimes even not at all.

Sealing tape is currently the most widely used, about this product we have introduced a lot in the previous content, in today's content, Xiaobian will mainly talk about the use of sealing tape and characteristics.

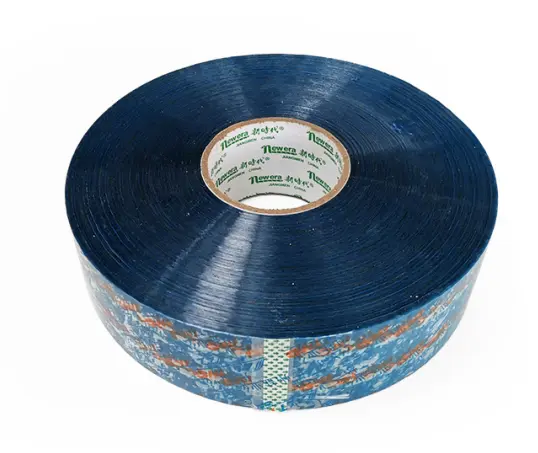

According to the different bonding interfaces, it can be divided into BOPP/paper, polished/paper, PET/paper, paper/paper, ink/paper, UV varnishing/paper strong and fast bonding. This adhesive separator adhesive and hand adhesive two categories, can also machine bonding and adhesive printing, basically meet the requirements of various packaging enterprises bonding materials.

Peculiarity:

1. The brushability is better, if you encounter thin products when manually brushing, you can also add water to dilute them, and stir evenly. The amount of water added depends on the type of sealing adhesive and the thickness of the material to be glued, and should be controlled between 2% and 10%.

2. The initial bonding speed is fast, and it can be bonded at high speed on the automatic sealing machine, and it can be pressed for half an hour when manually bonded.

3. The adhesive film is flexible, has good adhesion to the laminated surface and glossy surface, and has high bonding strength.

4. Good cold and heat resistance, the bonded product is baked at 60 °C for 72 hours or frozen at 10 °C (refrigerator emergency freezer) for 72 hours, the bonding strength remains basically unchanged, the product is not degummed, and the adhesive film is not brittle.

5. The adhesive film has flexibility and long-term pressure sensitivity, and its bonding strength is well maintained.

How to use and precautions:

(2) When using hand adhesive, the model of sealing glue is generally left to dry for 6-<> minutes after brushing, and then glued after the film is translucent to avoid glue overflow.

(2) The glue has a certain degree of moisture resistance, so when there is glue, it can be gently wiped with cotton yarn dipped in gasoline or ethyl ester solvent.

(3) According to its fast drying, it should not be repeated to avoid affecting the brushability.

(100) The amount of glue should be moderate, using manual brushing to glue, usually the amount of glue should be controlled at about 3g/m0, or according to the specific product bonding strength requirements, the specific amount of glue can be determined according to the speed of water absorption and temperature of the paper. Paper that absorbs slowly is less glued, less when the temperature is low, and vice versa. And after bonding, depending on the size of the stiffness of the bonded product, there must be enough pressure to ensure that the two adhesive surfaces are fully in contact and pressed for at least 5.<> hours before entering the next process.

(5) When using machine adhesive, the sizing amount should be controlled at the discharge port workpiece is not degummed, the sizing amount is too large, there is glue overflow, the sizing amount is too small will affect the bonding strength, the polished product because the substrate is too thin can be appropriately adjusted to avoid degumming at the discharge end.

Xiaobian's introduction today hopes to help you choose and buy sealing tape; For more related product information, please click: http://gb.adhesivetape.cc/Products_series.html